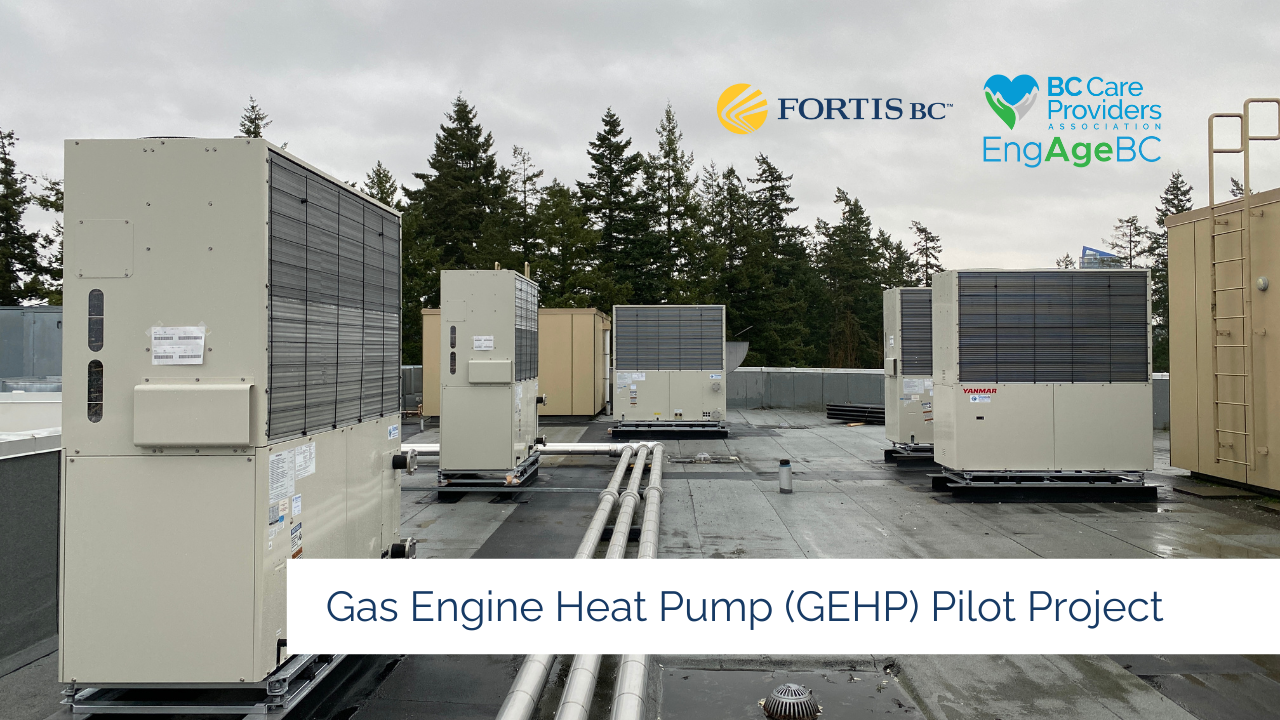

Thanks to our energy savings initiative, in collaboration with FortisBC Energy Inc. (FortisBC), three BC Care Providers Association (BCCPA) and EngAge BC member sites will receive more high-efficiency heating and cooling systems in their homes. Hawthorne Seniors Care Community and Baptist Housing (Evergreen Terrace and the Heights at Mt. View sites) have recently been approved for the Gas Engine Heat Pump (GEHP) Pilot Project with FortisBC (using natural gas or Renewable Natural Gas[1]), with installation currently underway at these three sites. The gas engine-driven heat pump installed in FortisBC’s GEHP pilot program is manufactured by Yanmar Energy Systems and distributed by Guillevin International Co. The purpose of FortisBC’s pilot program is to better understand how this technology works in real-world settings, measure energy savings and emissions reductions as well as gather participant feedback on the system.

Offering a combination of lower electricity consumption, high efficiency heating and cooling and simple installation and operation, the GEHP can provide both heating in the colder months and also cooling in the summertime for residents and staff. In comparison to a boiler, the GEHP saves 840 gigajoules and around 14% savings on estimated space heat consumption (approximately $10k annual costs saved). Moreover, this versatile machine can also offer domestic hot water and ventilation services. By using this technology, the manufacturer states that buildings can reduce their heating cost, expand cooling capacity by utilizing the existing piping and ducting system and not go through any expensive or disruptive infrastructure upgrades.

Through a gas engine, the GEHP heats and cools to provide better temperature control in seniors living and care settings. In the heating mode, the Yanmar heat pumps take heat energy from the outside air. Reclaimed heat energy is then added to the heat, with the compressor section increasing temperatures to a more suitable level. The heat pump’s internal heat exchanger then transfers the heat energy to the building hot-water heating system. As a result, the GEHP uses only a small amount of energy while providing powerful and efficient heating. Yanmar also proclaims that this mode provides a significant amount of reduction in electrical power consumption, with almost no energy loss, while further reducing greenhouse gas emissions as compared with a standard boiler.

Alternatively, the cooling mode takes excess heat from the room and into the heat pump unit. The heat is then transferred out of the system, or it can be set to recover the waste heat energy and be transferred to create “free” hot water heating for the domestic hot water system or other.

Following the installation stage early this year, FortisBC will be collecting data for the project assessment to quantify energy savings, utility cost savings and emissions reduction as well as qualitative feedback from the users to gauge the acceptance of this technology.

[1] Renewable Natural Gas (also called RNG or biomethane) is produced in a different manner than conventional natural gas. It is derived from biogas, which is produced from decomposing organic waste from landfills, agricultural waste and wastewater from treatment facilities. The biogas is captured and cleaned to create Renewable Natural Gas.